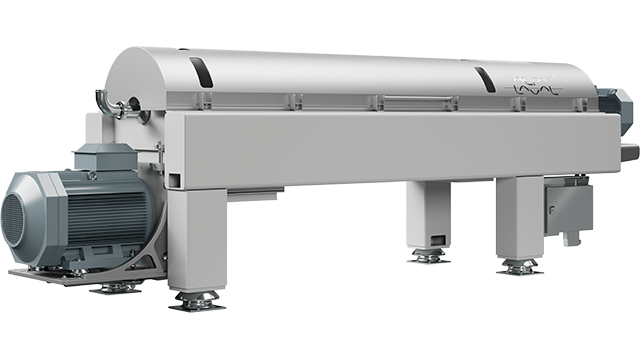

I-Dec

The Alfa Laval decanter centrifuge range of i-Dec is ideal for continuous sludge dewatering and thickening in municipal and industrial wastewater treatment, as well as potable water treatment. It is engineered for reliability, cost-effectiveness and simple operation, offering medium capacity and dry solids.

Experience fundamental solid-liquid separation in a cost-efficient way

- Low power consumption

- Highly reliable operation

- Low investment cost

- Small footprint

- Low noise emission

The i-Dec centrifuge for wastewater treatment delivers the same high quality, robustness and easy serviceability as our most advanced models. Its innovative design, incorporating patented solutions, operates in fully enclosed process sections, ensuring efficiency and reliability. Trusted by wastewater plants worldwide, it meets key performance criteria for thickening and dewatering sludge in a particularly cost-effective way, offering additional benefits such as easy operation, a small footprint, low ownership costs and quiet operation.

The features that make the difference

Everything you need to meet your challenges today – and tomorrow

With more than 60 years of experience in solid-liquid separation, Alfa Laval knows what it takes to deliver high-performance solutions for the wastewater industry. Packed with features unique to Alfa Laval, our decanter centrifuges provide improved efficiency, reliability and serviceability with each advancement.

FeedProtect

交換可能な耐摩耗保護を備えた供給ゾーン

独自設計のFeedProtect供給ゾーンは、製品をやさしく加速させ、乱流を最小限に抑えることで、摩耗と電力消費を低減します。この設計には交換可能な耐摩耗ライナーが装備されており、デカンター型遠心分離機の高い稼働率を実現します。

DeepPond

高い分離性能とエネルギー効率

ボウル内の池深さを増すことで容積が拡大し、滞留時間が長くなることで分離性能が向上します。DeepPond設計により、高流量でも固形物の乾燥度が高く、清澄なセンタレート(分離液)を得ることができます。

PowerTubes

ポンド深さの調整とエネルギー回収を可能にする液体排出口

PowerTubesの調整可能な排出口は、液体を回転方向に沿って接線方向に排出するよう設計されており、ボウルの回転をサポートすることでエネルギーを回収し、電力消費を最小限に抑えます。

FlightProtect

コンベヤスパイラルの摩耗を防止

FlightProtectは、コンベヤフライト専用に設計された耐摩耗性コーティングで、各フライトの構造を保護し、寿命を延ばします。

LiquidLock

Floating solids accelerator

A special device that accelerates floating solids from the surface into the solids layer. This results in liquids leaving the decanter centrifuge being of better quality.

How does a sludge dewatering centrifuge work?

Separation takes place in a horizontal cylindrical bowl equipped with a screw conveyor. The feed enters the bowl through a stationary inlet tube and is accelerated smoothly by an inlet distributor. The centrifugal force that results from the rotation then causes sedimentation of the solids on the wall of the bowl.

The conveyor rotates in the same direction as the bowl, but slightly slower, thus moving the solids towards the conical end of the bowl. A special patented Liquid-Lock conveyor design accelerates light particles before discharge for optimum separation. This also contributes to the small footprint of the unit.

Separation takes place throughout the entire length of the cylindrical part of the bowl. Relatively low G-force is needed for the i-Dec decanter to deliver good performance in terms of capacity and cake dryness. This contributes to low power consumption.

The clarified liquid leaves the bowl by flowing out of the casing viaspecial patented energy-saving PowerTubes that enable the effluent to discharge at lower speeds. The cake leaves the bowl into the casing through the solids discharge openings.

関連製品

Let us help you

Alfa Laval has been leading the wastewater decanter centrifuge market for decades. When partnering with Alfa Laval, you have full access to our application experts who can advise you on how to optimize your operations. And with the backing of our extensive service network, you always get quick assistance whenever you need it.