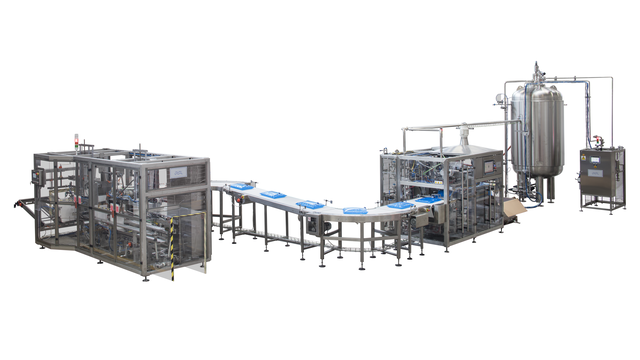

Aseptic bag-in-box fillers

Preserve product quality, sterility and shelf life with Alfa Laval aseptic bag-in-box fillers for industrial food processing. Products remain commercially sterile with pre-sterilized packaging and clean closures. Choose from a broad sustainable packaging portfolio, compliant with U.S. FDA requirements, ranging from pilot- to industrial-scale fillers for low- and high-acid food products, with or without particles.

A compatibility that no one else can match with our bag-in-box fillers

- Production flexibility no matter the bag size, cap type or packaging design

- Production safety using an aseptic validation protocol to ensure readiness for commercial production

- Global expertise, vast aseptic filling experience, and a service network with local service centres

- More uptime due to supervisory control and data acquisition (SCADA) solutions for real-time data monitoring and decision-making

- Complete solutions provider of aseptic lines, including sterilizers, aseptic tanks and aseptic bag-in-box fillers

Maximize uptime and minimize production losses with the Alfa Laval bag-in-box fillers. These reliable aseptic bag-in-box filling machines let you spend less time switching between sterilization in place (SIP), production and cleaning in place (CIP). The result? More product off your production lines and ready for distribution.

Safeguard your products, promote sustainability, and deliver quality, shelf-stable products using the Alfa Laval aseptic filler portfolio. Choose from pilot, compact, thousand-litre, high-speed low-acid aseptic filling machines for bag-in-box, bag-in-bin and bag-in-drum packaging. All bag sizes fit the semi-automatic and automatic fillers, boosting efficiency.

Let high-speed filling lift productivity and sustainability credentials while reducing the total cost of ownership.

Aseptic Bag-in-box filler selection guide

Pilot aseptic filler |

Compact aseptic filler |

Thousand-litre aseptic filler |

High speed low acid filler |

|

| Number of heads | 1 | 1-2 | 1-2 | 1 |

| 2" filling head for particles | ✔ | ✔ | ✔ | - |

| Low acid products | ✔ | ✔ | ✔ | ✔ |

| Ultra Clean Kit | - | - | - | - |

| Automatic bag feeding system (1") | - | ✔ | ✔ | ✔ |

| 3-20 litre bags- consumer use/catering | ✔ | ✔ | ✔ | ✔ |

| 200 litre bags- industrial use | ✔ | ✔ | ✔ | - |

| 1000 litre bags- industrial use | - | ✔ | ✔ | - |

| Max. speed (bags per hour) | 200 | 600 | 600 | 600 |

| Stainless steel totes filling option | ✔ | ✔ | ✔ | - |

| Filling with flow/mass meter | ✔ | ✔ | ✔ | ✔ |

| Filling with loading cells | ✔ | ✔ | ✔ | - |

| Hot filling version | ✔ | - | - | - |

| US Food and Drug administration (FDA) | - | Compliant | Compliant | Compliant |

| European Hygienic Engineering & Design Group (EHEDG) | - | - | - | Compliant |

ユーザー成功事例

Frut X社、アルファ・ラバルとの協業でトマト収量が3倍に。800人以上の農家の収入向上を実現。

スタートアップの食品加工メーカー Frut X Industries は、アルファ・ラバルと協力し、多用途対応の果実・野菜加工プラントを設計・建設しました。アルファ・ラバルの迅速な納入、トレーニング、ベストプラクティスの提供により、このプラントはわずか6か月で本格稼働を開始。酵素管理の最適化によって収率、食感、色味、安全性が向上し、さらに生産ライン全体で凝縮水を再利用することで、Frut X社のサステナビリティ目標の達成にも貢献しています。包括的なサービス契約を含むこのエンド・トゥ・エンドのパートナーシップは、地域農家のコミュニティを支え、Frut X社の成長を後押ししています。