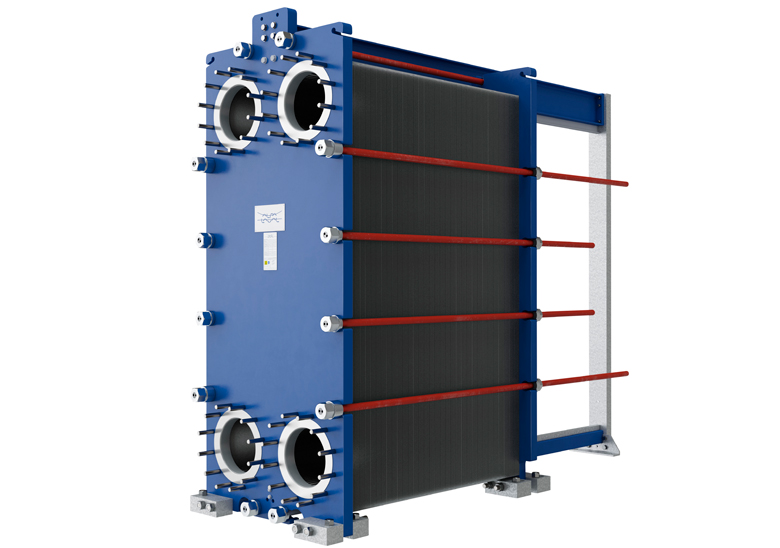

There is a wide variety of Industrial gasketed plate heat exchangers that can be used in all types of industries. The number of sizes, plate and gasket materials, and available options are enormous.

There is a wide variety of Industrial gasketed plate heat exchangers that can be used in all types of industries. The number of sizes, plate and gasket materials, and available options are enormous.

The Industrial line’s versatility allows it to be designed and configured for applications ranging from relatively simple duties with low requirements to very demanding duties with the highest requirements on both performance and documentation. The products are used for heating, cooling, heat recovery, condensation, and evaporation.

Learn more about the benefits of GPHEs vs. shell-and-tube heat exchangers

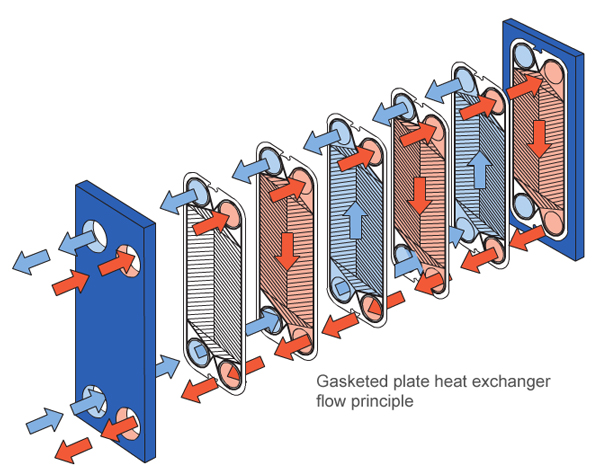

The heat transfer area of a gasketed plate-and-frame heat exchanger consists of a series of corrugated plates, assembled between the frame and pressure plates, which retain the design pressure. The sealing between the plates is made of gaskets. For the highest thermal performance and to enable a very close temperature approach, fluids normally run counter-currently through the heat exchanger.

The Industrial line is available with various pressing depths and angles of the chevron pattern and various shapes of the corrugation which are all carefully designed and selected to achieve optimal performance. The CurveFlow™ and the chocolate pattern distribution area are two design features available that ensure fluids are evenly distributed across the entire plate. The result is that the entire heat transfer surface is fully utilized and stagnant zones that can result in fouling are avoided.

High flow turbulence between plates results in higher heat transfer; however, the consequence is pressure drop. Our thermal design engineers can help you design and select the model and configuration that is suitable for your application needs while delivering maximum thermal performance and minimizing pressure drop.

It's important to understand that all gasketed plate heat exchangers are not the same. The features highlighted below are important components to look for in a GPHE, and when combined, these features offer extensive benefits, such as reduced total cost of ownership, higher efficiency and increased staff safety.

One of the most important features of a plate heat exchanger, the distribution area ensures full use of the heat transfer area and minimizes fouling.

An inefficient distribution area with uneven flow causes maldistribution and fouling build up.

A glue free gasket with superior alignment that ensures a perfect seal and trouble-free maintenance. Fastening to the plate is improved by having five fastening points.

Other gasket designs, such as snap-in gaskets, only have one fastening point to the plate. If this one point is lost, there is no gasket fastening function.

Swing feet can simply be swung to the side for service, allowing for quick and easy opening of the unit while maintaining its seismic rating.

Most plate heat exchangers have feet that are bolted or welded to the frame and/or pressure plate. These feet are more likely to get stuck, and they also have to be completely removed for servicing.

Corner guiding keeps plates aligned throughout the entire plate package during closing of the heat exchanger. The plates are designed with corners that lead the plates into position and help stabilize the plate pack during the tightening procedure.

The lack of a proper alignment system may allow the plate pack to move in any direction, leading to wavy plate packs with leakage problems.

The pressure plate must be easy to move and slide along the carrying bar in order to gain access to the plate pack. The most common solution is a roller on top of the carrying bar, making it easy and less time consuming to conduct service. The roller should be made out of metal to be able to carry the weight of the pressure plate.

The mechanical solution of the roller can be more or less robust. The risk is a pressure plate that is jammed and impossible to move when it is time to conduct service.

A device between the tightening bolt head and the frame that reduces friction forces and makes service easier.

Opening and closing the PHE without bearing boxes is time consuming and increases the risk of paint damage, which can lead to corrosion damage.

Keeps the plates aligned during closing of the plate heat exchanger that facilitates service.

Many alignment systems do not close the vertical gap between the carrying bar and the plate, leading to wavy plate packs with leaking problems.

Plate heat exchangers have an essential role in most applications. If they function poorly, they may lead to lower product quality, reduced safety and higher energy costs. And if they fail, they can lead to costly downtime and major losses in production. This makes it important to perform maintenance – and important to do it correctly.