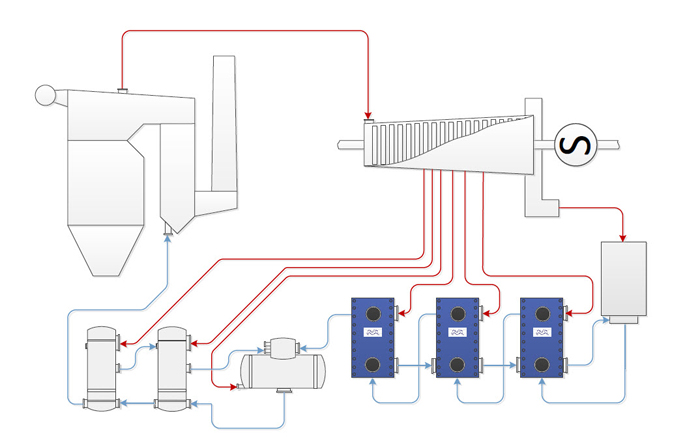

Feed water preheating

Good economy for power generation depends largely upon efficient feedwater preheating. Alfa Laval solutions combine the robustness of shell-and-tube heat exchangers with the high performance, easy maintenance and minimal footprint of plate heat exchangers. This reduces capital investment as well as operation and maintenance costs.

Optimizing feedwater preheating systems

Alfa Laval solutions to preheat feedwater for steam cycle power generation provide superior heat transfer efficiency. Less steam is required to preheat the feedwater, which means more steam can be supplied to the turbines thereby increasing the electrical output. It also means that less fuel is required to preheat feedwater to a higher temperature.

Highly efficient feedwater preheating

Our feedwater preheaters, such as the all-welded plate heat exchanger Alfa Laval Compabloc or DuroShell, have been developed to meet the specific requirements of the power industry. These perform well under virtually any power plant operating conditions and comply with pressure vessel codes including PED and ASME VIII div 1.

Superior to shell-and-tube solutions

Alfa Laval feedwater preheaters offer these advantages over conventional shell-and-tube heat exchangers:

- Tighter pinch point: Provides better utilization of the latent heat in the condensate This in turn means that less extraction steam is required to perform the same preheating duty or to raise the feedwater temperature in the boiler. This results in higher electrical output and significant savings because less fuel is required to obtain the required feedwater temperatures.

- Smaller size: The combination of an Alfa Laval Compabloc and DuroShell requires about 80% less space to perform the same duty as a horizontal shell-and-tube heat exchanger. Plus the maintenance area required for Compabloc is almost 90% smaller than the area required by shell-and-tube units. In addition, Alfa Laval feedwater preheating solutions fit on one level while a vertical shell-and-tube installation requires two or three floors, which makes the steel construction more complex and more expensive.

- Easy to access, easy to clean: Our feedwater preheating solutions provide 360° accessibility and 100% cleanability due to an easy-to-remove panel on each side of the Alfa Laval Compabloc. This means the time between cleaning intervals are longer than those required by shell-and-tubes thereby optimizing plant operating conditions and economy.

Downloads

Efficient feedwater pre-heating