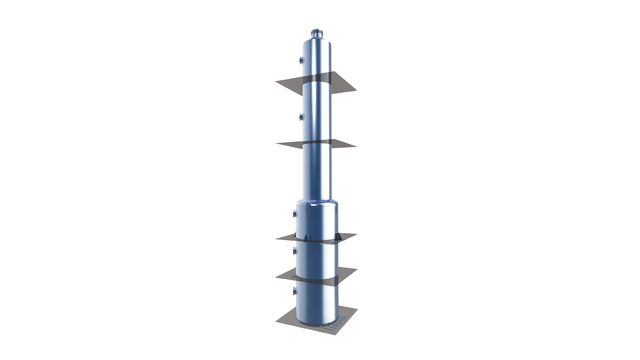

SoftColumn

At Alfa Laval, we don’t just make do with traditional deodorization thinking – we develop new and better ideas that later set the standard for the whole industry.

Deodorization is such a crucial part of edible fats and oils processing that the only way to really get ahead – and stay there – is to use the latest technology and the best equipment.

Alfa Laval’s patented breakthrough in applying thin-film technology to modern deodorization processes opens up important opportunities for taking your processing efficiency to a new level. It enables you to use less steam and to process the oil at lower temperatures. This results in more gentle, effective treatment that greatly benefits the quality of your fats and oils.

The Alfa Laval SoftColumn™ deodorization concept is also designed to be extremely versatile. Separate stripping and retention sections provide a wide range of options for implementing the most efficient deodorization solution currently available – both in new installations and when extending and updating existing fats and oils processing installations.

動作原理

How the deodorization process of edible oil works

The deodorization process removes unwanted odours, flavours, and impurities, improving the oil quality and shelf life. It begins with deaeration, which removes the air to prevent oxidation. The oil is then gently heated using heat recovered, improving energy efficiency. In the deodorization system, the oil passes through stripping and retention sections under vacuum and steam, removing volatile compounds such as free fatty acids. Cooling and polishing filtration then produce a clean, stable, high-quality final product. The process is key to delivering safe, appealing edible oils for both food manufacturers and end consumers.

The deodorization process starts with deaeration

Before heating the oil, air must be removed under vacuum (deaeration) to protect product quality by preventing oxidation. After leaving the deaerator, the oil is regeneratively heated in a special heat exchanger, an economizer, using the hot oil leaving the deodorization column to recover as much heat as possible. The oil then passes through a final heater, reaching the precise temperature required for deodorization, typically using high-pressure steam.

Stripping and retention in the deodorization system

Once at the designated temperature, the heated oil enters the deodorization column, the core of the deodorization system. The column may include a stripping section and a retention section. The oil passes through the stripping section under vacuum, and steam removes volatile impurities, including free fatty acids (FFAs) that have a higher vapour pressure than the main components of the oil itself. If present, these volatiles can affect the flavour, odour, and stability of edible oils.

The oil then resides in a retention section for a specified period of time for thermal treatment known as heat bleaching to remove undesirable pigments and ensure the stability of the final product. The duration in the retention section depends on the desired product specifications.

Condensing removed impurities

Volatile impurities removed during the deodorization process are condensed in a scrubber using cooled, recirculated distillate. The scrubber may be placed on top of the stripping section or installed as a separate unit.

Final cooling in the deodorization process

Here, the oil undergoes two-stage cooling. It is cooled in the economizer to achieve the specified final temperature and then undergoes polishing filtration. It is then transferred for subsequent processing, storage, or packaging